Marine Safety Equipment: 5 Key Characteristics for Coated Textiles Marine Use

Marine SafetyJun 8, 2021

Marine safety equipment must meet stringent criteria and comply with regulations to be used on the field. Several new technologies and processes introduced recently can help improve the functionality and durability of marine equipment.

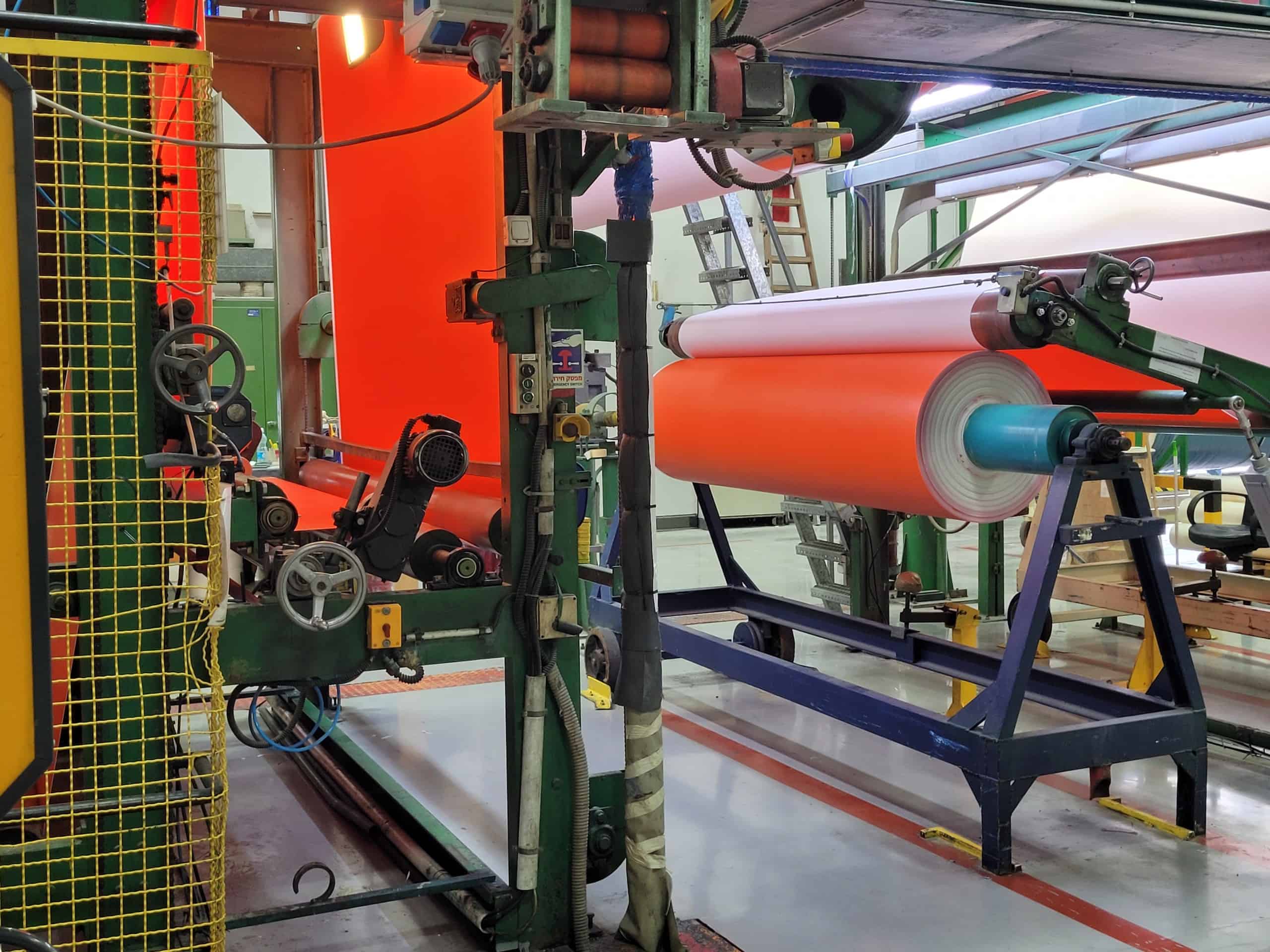

TPU coated textiles are among the many versatile options with specific properties required for marine safety equipment. Today, end-products like life rafts, life vests, and emergency evacuation slides are slowly shifting towards TPU coated textiles because of their advanced features and general convenience.

In this article, we look at the 5 key characteristics that make TPU coated textiles a suitable choice for marine safety equipment.

1 – Compatibility for inflatable marine safety equipment

Generally, marine safety products are either always filled with foam or are immediately inflated when required. Life vests, life rafts, and evacuation slides are usually inflated when needed.

TPU Coated textiles are a great choice for both applications because of their air-holding capacity and foldability (when not inflated). PU-coated textiles can be joined using welding techniques and adhesives. Both processes can deliver your required results, but welding is preferred nowadays because it’s versatile, durable, and more reliable for long-term air containment.

The welding process itself is also time-efficient and convenient compared to other methods, which makes it the preferred bonding method of manufacturers.

2 – Resistance to chemical and environmental degradation

Products used in the marine environment need to be resistant to chemicals, and other elements found in the harsh marine environment. You don’t get to use safety equipment often and sometimes they remain on board for several years unused. If your application is expected to withstand extended exposure to heat, fuel or abrasion, the material needs to be able to retain all of its properties for long time periods.

TPU Coated textiles have that capability. They can be easily stored and will resist exposure to all elements.

3 – Durability and flexibility

TPU Coated textiles have the excellent capability to bend, stretch, and undergo other physical changes without losing their inherent capabilities. They undergo several treatments and processes that increase their overall durability, strength, and other physical characteristics.

These inherent qualities make coated fabrics ideal for marine safety applications where you have to deal with different requirements.

Life vests, rafts, evacuation slides, and boats need to work in the same environment but their actual applications are entirely different. TPU Coated textiles are one of the few materials that can cater to all these different requirements and perform consistently.

Another excellent quality of TPU coated textiles for marine applications is durability. While not 100% impervious, TPU coated fabrics can resist most external damage and don’t degrade with time. These qualities are ideal for marine equipment where you need reliability because you can’t have a contingency measure failing in real-time.

4 – Suitability for storage in marine environments

Life vests, personal floatation devices, and rafts often need to be immediately deployable in case of emergencies. That’s why they are usually stored in central locations on deck. TPU coated fabrics are ideal for storage under such conditions with consistent exposure to heat and abrasion and even chemicals.

Inflatable Equipment made of rubber, (or PVC) are other popular choices for marine safety equipment, but the disadvantage with these fabric types is in extended storage time. When folded (blocking) the folds often stick to one another. As a preventative measure, it’s a common practice to apply special powder on rubber equipment.

TPU Coated fabrics do not have that weakness of sticking to themselves. The material can easily resist any physical degradation due to high temperatures on the deck.

5 – Versatility complying with international standards

Marine safety products have varying applications in all kinds of vessels. From a personal yacht to a major commercial liner, they’ll comply with stringent safety standards set by international institutions like the ISO 12402 or UL 1191 and IMO resolutions.

Complying with international standards usually restricts the number of solutions you can adopt. However, the right supplier can deliver a variety of solutions that comply with particular standards. You can even develop a customized solution that focuses more on a certain aspect required for your specific application as long as it complies with the standard.

With the right material partner, you can circumvent the usual limitations and develop unique solutions that give you an edge over your competitors.

Get the best marine safety solutions with Erez

The technology behind marine safety equipment has improved considerably and manufacturers need to pay attention to them while updating their equipment.

Erez is one of the most trusted names in the marine safety industry and has been supplying top-quality materials for life vests, rafts, personal floatation devices, and other safety devices.

With around 3 decades of experience, Erez is more than just a supplier. It takes pride in being a source of knowledge and guidance for its partners and helps them come up with the best solutions for their needs.

That’s not all! Erez has an advanced R&D team and continues to lead the industry with its innovative solutions that allow you to create stronger, more functional, and long-lasting marine safety equipment at a lower cost.

Share this Post