If Your Factory Works with Marine Textiles – Consider These Top Technologies for 2018

Marine SafetyJun 4, 2018

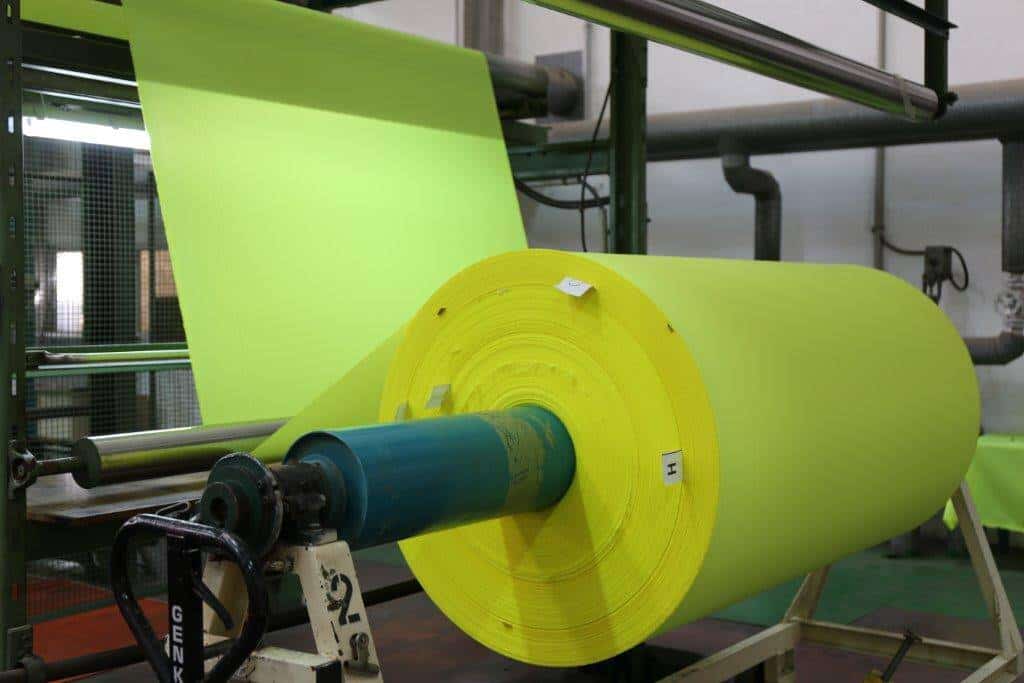

Whether you use coated textiles to manufacture marine safety equipment such as life jackets ( PFDs) or life rafts, or boating products like foam- or inflatable-collar boats, your product lines evolve and so do the requirements for the materials you use. Erez understands that you are always looking for new, precision, high-quality coated textiles. So, we constantly invest resources into researching and manufacturing new products and processes to meet your needs. Every year, our innovations provide you with wider choices in material types and manufacturing processes that allow marine textiles to be increasingly customized to your end-use applications. Erez’s 2018 innovations include new textiles that are stronger and more customizable than ever, as well as advanced welding techniques to make your products even stronger than before.

Material Innovations

Erez has advanced the material coating process to provide you and your end-user with coated textiles that have increased strength and tear resistance, resist harsh environments more effectively, and still perform as expected every time they are used. Our innovative materials can be welded or glued, if needed to produce seams that are stronger than the original material.

One of these innovations is Erez’s breakthrough technology for polymer plasticizers used in the PVC-alloy coatings. These new ER (PVC/EVA-alloy) coatings withstand extreme external and chemical conditions and lengthen the life of the coated textile beyond the capabilities of monomer plasticizers.

Erez technical marine textiles, including TPU, PVC, and PVC/EVA-alloy coatings on a wide variety of nylon and polyester base cloth, meet all requirements for color, permeability, tensile strength, UV resistance, and international regulations.

Welding

Unlike rubber-coated textiles which can only be bonded by using glue, modern TPU-coated textiles give you the option to weld seams using methods such as hot air, high frequency (RF), or ultrasonic. Since the welding process uses automated machinery, the process is faster and reduces the manual labor involved. Welding does not expose workers to potentially dangerous gluing chemicals and keeps them away from the actual bonding process helping to ensure their physical safety.

The strength and integrity of the bonds, as well as the ease which with the bonding process fits into your manufacturing process help determine the end-use specifications. Erez offers the advantages of advanced welding processes that produce bonds with higher strength and longer wear than glued bonds and fit easily into a manufacturing line. Reduce your labor costs and increase the quality of your products by using weldable coated textiles.

Less Textiles in the Landfill

PVC coatings have gained a poor reputation regarding their environmental impact. Erez is working to decrease the environmental impact of these coated textiles, as well as TPU-coated textiles, by creating textiles with significantly longer end use. This helps to decrease the amount of material that needs to be produced over all and gives the end consumer a high-quality product that will last for years of use.

Your Solutions

As a manufacturer, you don’t want your design capabilities limited by fabrics, coatings, or bonding technologies. You want technical textiles that meet your specific requirements. Because Erez is constantly innovating, now, more than ever, we can offer you technical fabrics customized to your specific end-use applications and are greener at the same time. Learn more about coated textile technologies as they apply to the marine safety industry in our 2018 Marine Safety Textile Technology Report. Download your complimentary copy now.

Share this Post