How Aliphatic TPU Gives Your Product an Advantage Over the Competition

coated textile sourcingNov 29, 2020

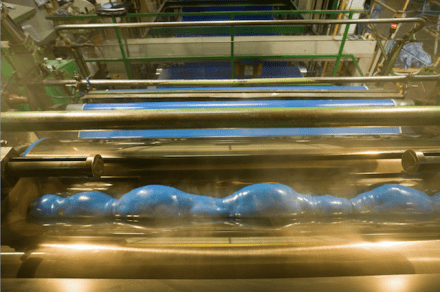

Thermoplastic polyurethane (TPU) is widely used in manufacturing for all sorts of outdoor equipment. Compared to other types of plastics, TPU offers excellent performance at low temperatures, extremely high impact strength, and resistance to weather, UV radiation, and a wide variety of chemicals. Plus, TPU can be welded, which makes it much more versatile for products like inflatable boats and kayaks, flexible (collapsible) storage tanks, medical devices, life rafts, jackets, and more.

Over the past few years, demand for TPU materials has skyrocketed. Most of this demand is for a specific type of TPU known as aromatic TPU, which is easy to produce and widely available.

However, Erez has pioneered a variety of new products using a type of TPU known as aliphatic TPU. In this article, we’ll take a closer look at this TPU fabric and why it’s superior to aromatic TPU for many applications.

Aliphatic TPU vs. Aromatic TPU: What’s the Difference?

The difference between aliphatic and aromatic TPU materials lies in their chemical composition. TPU is a multi-phase block copolymer and combines a soft and a hard segment. The soft block is responsible for the flexibility and elastomeric character of TPU while the hard block gives the toughness and physical performance properties.

This small difference in chemistry results in a big difference in the behaviors of the two TPU types. Aliphatic TPU won’t oxidize under UV radiation, making it one of the most stable coating compounds available for outdoor applications – Color stability upon UV exposure, Nonyellowing appearance. Aromatic TPU coatings, on the other hand, can break down over time if left in the sun. For any products that spend much of their usable lives outdoors – including inflatable boats and flexible storage tanks – the ability of aliphatic TPU to withstand oxidation from sunlight is a significant advantage.

Superior in Durability

Another benefit to aliphatic TPU is it’s superior resistance to hydrolysis and surface abrasion compared to aromatic TPU. That means products that use aliphatic TPU are more durable against scratches and harsh weather conditions. If you’re building an inflatable boat, storage tank, aliphatic TPU’s enhanced abrasion resistance can dramatically increase the lifespan of your products.

Low-Temperature Performance

Aliphatic TPU doesn’t lose any ground to aromatic TPU when it comes to cold weather adaptability or solvent resistance. So, there’s virtually no downside to using an aliphatic TPU coating as opposed to using an aromatic TPU coating.

Chemical Resistance

Another key advantage is it’s resistant to a wider variety of chemicals. Many chemicals that degrade aromatic TPU don’t have the same negative effect on aliphatic TPU. For this reason, aliphatic TPU is highly preferred for use in products that come in contact with potentially oxidizing chemicals such as medical devices, storage containers, and booms.

The Product Lifespan and Additional Benefits of Aliphatic TPU

While all of these properties of aliphatic TPU are important for the usable lifespan of your products, aliphatic TPU has additional benefits that your customers are sure to notice. Unlike aromatic TPU, aliphatic TPU is Hypoallergenic, odorless, and doesn’t yellow or fade over time. As a result, your products can retain their original coloring for years.

Erez is Pioneering Aliphatic TPU Applications

While most material suppliers are still offering aromatic TPU, Erez has been busy pioneering aliphatic TPU products that no one else in the industry can offer. Erez specializes in producing aliphatic TPU and offers exclusive solutions for its partners.

With Erez aliphatic TPU fabric and expert manufacturing guidance, we can help you take your products to a whole new level that your competitors simply can’t match.

Share this Post