In industrial manufacturing, identifying and selecting joining methods is a serious topic in constructing products made of coated textiles. Among these methods, High-Frequency Welding (HFW) stands out as an advanced and efficient technique.

Coated textiles are an integral part of numerous products like tarpaulins, tents, inflatables, and protective clothing. The application of HFW in manufacturing these items ensures strong, watertight seams that withstand rigorous use, enhancing the overall resilience and life of the product.

HFW, sometimes referred to as Radio Frequency (RF) welding, or dielectric welding, utilizes electromagnetic energy to generate heat and fuse materials together.

In this article, we will explore the science behind High-Frequency Welding thermoplastics, its applications, and what sets it apart from other welding methods. We’ll also delve into the structure of HFW machines, safety considerations for operators, necessary training, and a glimpse into the future of this transformative technology.

The Science Behind High-Frequency Welding

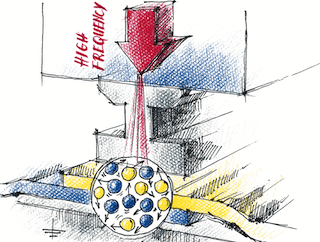

High-Frequency Welding (HFW), alternately known as Radio Frequency (RF) or Dielectric Welding, is an advanced fusion technique used to bond materials using a rapidly alternating electric field. This distinct process involves applying the electric field between two bars, precisely in the joint area, to create a robust fusion between the materials at the molecular level.

Materials Effectivity

Essentially, High-frequency welding is effective only on thermoplastics that exhibit a high dielectric constant. The dielectric constant of a material is a measure of its ability to store electrical energy in an electric field — a property determined by two factors: the molecule’s geometry and its dipole moment. A dipole moment refers to the measure of the molecular polarity, which indicates the separation of electrical charges within the molecule that forms an electric dipole.

How the Heat is Generated

In the HFW process, when thermoplastics with a high dielectric constant are exposed to alternating current, the dipole molecules within the polymer attempt to flip to realign themselves with the new field orientation. This rapid reorientation creates substantial intermolecular friction, thus generating heat.

How The Weld Forms

As the generated heat causes the polymer to reach its glass transition temperature, effectively causing it to melt, pressure is then applied at the joint by the bars until the material cools down. During this process, the molecules from both materials intermingle, forming a weld that can be as robust as the original materials themselves.

On the other hand, materials characterized by a low dielectric constant do not react to the alternating current as effectively. Their molecules either flip very slowly or not at all, which means the required heat needed for the fusion is not generated. Consequently, these materials do not form a weld.

For more information on welding techniques that are right for your application, download the Erez Ultimate Guide to Welding Coated Technical Textiles.

Applications of High-Frequency Welding in Coated Textiles

High-Frequency Welding (HFW) is a remarkably versatile process, offering a practical welding solution for a wide range of materials. The typical welding cycle times for HFW range from two to five seconds, accommodating material thicknesses varying approximately from 1/1000” to 50/1000” (25.4 μm to 1270 μm).

One significant advantage of HFW is its ability to heat from the inside out. Unlike many other welding techniques in which overly thick materials may not bond in the middle because the core fails to melt, while the outer layers overheat or burn, HFW efficiently circumvents this issue. It ensures thorough heating and bonding of materials, making it an excellent method for forming airtight seams.

Best Coated Technical Textile Materials for High-frequency Welding

In the realm of technical textiles, HFW is commonly used on materials coated with Polyvinyl Chloride (PVC), Ethylene Vinyl Acetate (EVA) alloys, Thermoplastic Polyurethane (TPU), and polyurethanes (PU). Although it’s possible to use HFW to weld other polymers like nylon, Polyethylene Terephthalate (PET), PET-G, A-PET, EVA, and some Acrylonitrile Butadiene Styrene (ABS) resins, special conditions are often required. For instance, nylon and PET can be successfully high-frequency welded if the welding bars are preheated.

Applications HFW Isn’t Ideal For

HFW generally doesn’t work well with materials like polypropylene (PP), polyethylene (PE), Polytetrafluoroethylene (PTFE), polycarbonate, polystyrene, polyethylene, or polypropylene. Due to PVC restrictions, a special polyolefin grade has been developed for industrial applications. This innovative material can be HF welded, significantly expanding potential uses in manufacturing.

The diversity of materials compatible with HFW has led to its wide use in many industries. HFW is crucial in medical supplies, particularly for manufacturing TPU-coated nylon products. Less frequently, the technique is applied to specialized polyester materials in healthcare manufacturing.

Applications HF Welding Is Commonly Used In

The technique is commonly used in applications such as protective clothing, gel- and foam-filled cushions, lumbar support items, hydration reservoirs, and medical air and water mattresses. It’s also used to manufacture covers for stretchers and beds.

In essence, High-Frequency Welding’s versatility and efficiency position it as an invaluable tool within the coated textiles industry, with a vast array of applications that span multiple sectors, from technical textiles to crucial medical supplies.

Advantages of High-Frequency Welding

High-Frequency Welding (HFW) carries numerous advantages over traditional welding techniques. Its unique operating principles and versatile applications offer various benefits, from aesthetic enhancements to efficient energy control. Here are some of the significant advantages of HFW.

Decorative Elements

High-Frequency Welding allows for the incorporation of decorative appearances or embossing on the welded items. This is possible by engraving or profiling the welding plates. These aesthetic enhancements offer additional value to the final product, making HFW a preferred choice for manufacturing a variety of consumer goods.

Efficient Welding and Cutting

By incorporating a cutting edge adjacent to the welding surface, HFW can simultaneously weld and cut the material. This method, often referred to as “tear-seal welding,” compresses the hot plastic sufficiently to allow excess scrap material to be torn off. This dual action enhances productivity and reduces manufacturing time.

Targeted Heating

HFW focuses the heat at the welding target, ensuring the surrounding material does not superheat and risk burning to achieve the target temperature at the joint. This targeted heating prevents damage to surrounding areas of the material and ensures a high-quality weld seam.

Controlled Energy Application

In HFW, heat is generated only when the field is energized. This offers greater control over the amount of energy that the material is exposed to throughout the welding cycle. The material can remain under pressure without introducing more heat, making it possible to instantly heat, weld, and cool the material under compression, thereby increasing the weld strength.

Prevents Heat-Degradation

Unlike other welding methods where heat radiates off the plates, potentially degrading the material surrounding the weld, HFW-generated heat remains localized. This feature helps prevent heat-degradation of the material adjacent to the weld, ensuring the integrity of the overall product.

Anatomy of High-Frequency Welding Machines

High-Frequency Welding (HFW) machines are complex pieces of equipment, designed to provide efficient, precise welding by harnessing the principles of electromagnetic energy. These machines consist of several key components, each playing a crucial role in ensuring a successful welding process.

1. High-Frequency Generator (Oscillator)

The generator, is often referred to as an oscillator. It serves as the source of the high-frequency alternating current necessary for the HFW process. It’s pivotal for creating the rapidly alternating electric field required for HFW.

2. Pneumatic Press

The press is an essential component that applies the necessary pressure during the welding process. In many HFW machines, pneumatic presses are used due to their reliability and ease of control. The pressure exerted is critical in ensuring a robust and durable weld.

3. Electrode

The electrode transfers the high-frequency current from the generator to the material being welded. Often referred to as bars, these components precisely deliver the electromagnetic field to the joint area. They also apply the necessary pressure during the welding process and can be tailored with specific profiles for tasks like embossing or cutting.

4. Welding Bench

The welding bench holds the material in place during the welding process. It provides a stable platform that ensures precise alignment and secure positioning of the materials being fused.

5. Control System

Operators use the control system to adjust the field strength based on the material being welded and the type of machine being used. The control system also manages other parameters such as power levels, welding time, cooling time, and pressure. Modern HFW machines often feature sophisticated control systems with touch screen interfaces and programmability for different welding parameters.

The frequencies permitted for HFW of thermoplastics are 13.56, 27.12, and 40.68 megahertz (MHz). Among these, 27.12 MHz is the most popular industrial frequency due to its effectiveness and compliance with most international regulations.

Safety Measures in High-Frequency Welding Operations

Given the use of electromagnetic fields and high-energy equipment, operators must adhere to stringent safety guidelines to prevent accidents and health hazards.

One key safety consideration in HFW is the radiation of high-frequency (HF) fields from the welding machine. Generally, machines with visible open electrodes, which are unshielded, tend to emit stronger fields than those with enclosed electrodes. However, the strength of the field diminishes sharply with distance from the source.

Despite the rapid decrease in field strength with distance, close proximity to the welding machine, where the field is strongest, can affect the human body and potentially cause harm or discomfort to operators.

Here are some crucial safety measures:

Shielding

Proper shielding of welding machines can help minimize radiation of HF fields. This can be particularly important for machines with open electrodes.

Distance

Where possible, operators should maintain a safe distance from the active welding machine to minimize exposure to HF fields.

Personal Protective Equipment (PPE)

Operators should wear appropriate PPE, which includes gloves and safety glasses, when operating or working near HFW machines.

Training and Awareness

Operators must receive thorough training from experienced in-house personnel or manufacturers’ representatives at their site. In-depth knowledge pays off through improved production quality, reduced shutdown time, lower repair costs, and enhanced safety.

Regulated Exposure

Governments often regulate the maximum exposure to HF fields for operators of HF equipment. Operators and management should be well aware of these regulations and ensure compliance.

By incorporating safety precautions, operators can minimize potential hazards and create a safe working environment. It’s crucial for any organization employing HFW to prioritize safety training and ensure their adherence to regulatory guidelines.

Manufacturer of Top-quality Coated Thermoplastics

At Erez-therm, we pride ourselves on being a premier manufacturer of top-quality coated thermoplastics. We have been supplying to technical textiles for some of the best brands worldwide. With 40+ years of experience, we’re not just a supplier but strategic partners committed to our clients’ success. Our deep understanding of your specific applications allows us to pinpoint the best solution and tailor it to your needs.

While we excel in coated thermoplastics, we are not manufacturers or authorities on High-Frequency Welding equipment. We focus our expertise on materials, not on the machinery used in their fabrication. Our primary focus remains dedicated to crafting high-quality coated thermoplastics while adding value to our clients through our insurmountable knowledge and expertise.

For more information on welding techniques that are right for your application, download the Erez Ultimate Guide to Welding Coated Technical Textiles.

Share this Post