In the modern industrial world, coated technical textile applications play an essential role across many industries ranging from the energy sector to agriculture, the military and more. Due to the nature of such applications, the coated fabrics they rely on require consistent and reliable performance.

In this article, we’ll discuss the importance of consulting a manufacturer who can offer you a customized coated fabric for your project and how such a solution compares to a generic choice that seemingly fulfills the criteria.

Why Customize with a Coated Fabric Manufacturer?

During the R&D phase, you may be able to find generic coated fabrics that meet your basic criteria and require minimum investment. Then why contact a coated fabric manufacturer? How different will the results be?

If you are contemplating between these two paths, we offer 3 reasons why to involve a coated fabric manufacturer in your production process.

1– Quality Compliance

Generic options that are easily available in the market may have attractive price tags but when it comes to quality, inconsistency is common. In some cases, you’ll even find multiple issues in a single roll. For end products like inflatable marine safety equipment, first responders gear, or environmental protection solutions, the cost of failure in performance is too great.

Communicating with a professional coated fabric manufacturer is the first step to getting a product that is fit for your application that will perform with reliability and consistency. Here are the basic elements you can look at to know that a manufacturer can deliver the required quality.

Raw Materials

The quality of the product as far as consistency and performance is first and foremost determined with the raw materials used in the fabric. A given fabric consists of raw materials such as filaments, yarns, coating materials, additives, pigments etc. When sourcing from a coated textile manufacturer, you can be ensured as to the quality level of the raw materials they use.

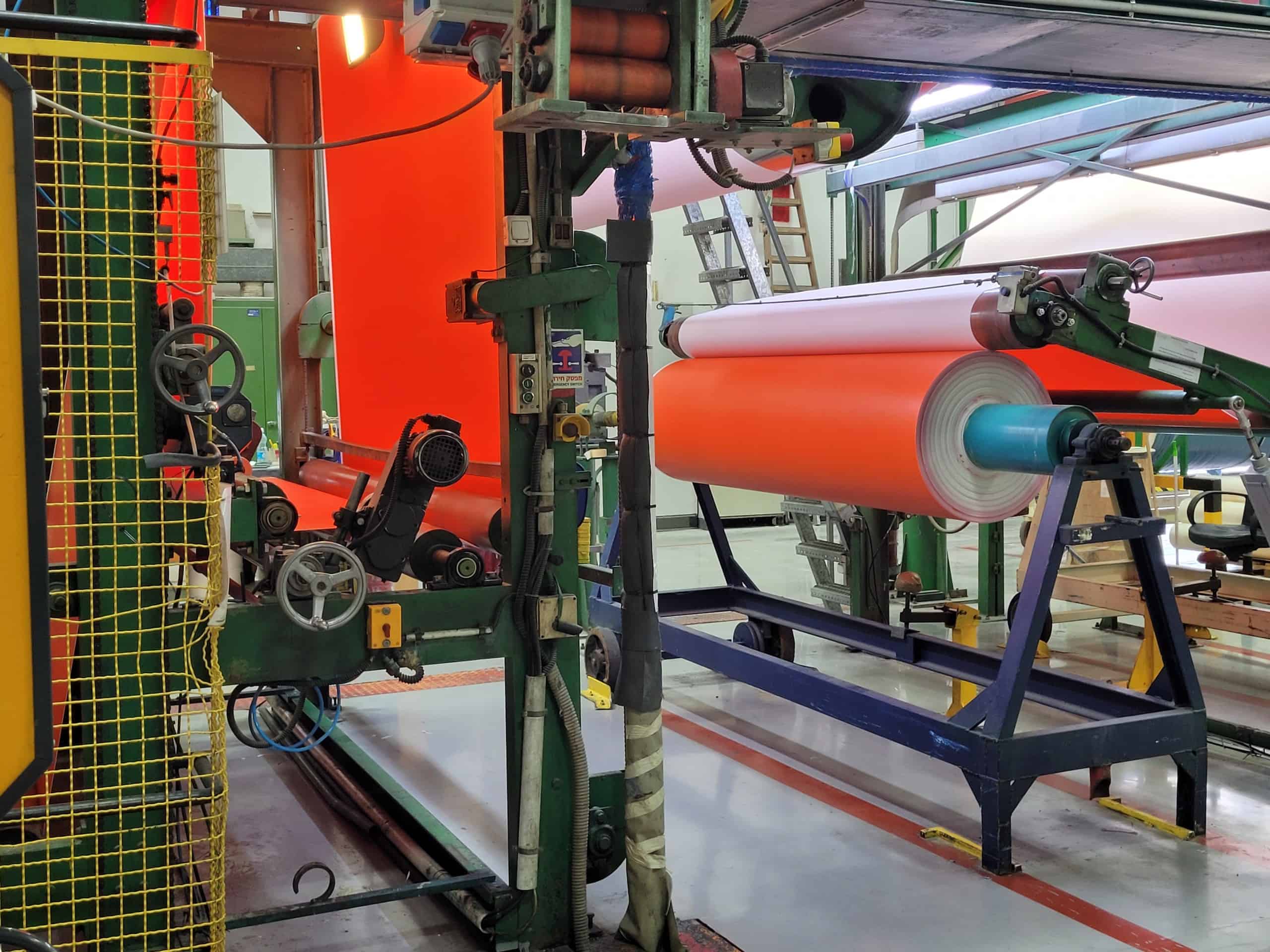

Manufacturing Process

Elements of a high-quality coating manufacturing process include high-end equipment and machinery. The process must have controlled procedures in place, it must be monitored so that the precise settings are maintained such as speed, temperatures, tensions, and pressures. Furthermore, the output must have a high level of consistency, and traceability.

Testing

If your product is intended to apply for a public tender by government agencies, your product must comply to international standards on the component and production level. Sourcing from a coated fabric manufacturer that has robust quality control procedures in place will ensure that your project fully complies with those standards.

2 – Innovation Backed By Years of Experience

A coated textile manufacturer can leverage its rich history of customized coated fabric solutions for a range of clients and applications across multiple industries when determining a solution that will give your project an advantage customizable solutions allow you to become creative. With a technical coated textile manufacturer, you can innovate according to your requirements by focusing on a certain characteristic without compromising on quality.

Beyond customizing a fabric for performance, an experienced textile partner can also account for your specific production methods. For example, supplying the right fabric according to your method of seams binding whether you use glue, hot air welding or wedge welding.

3 –Product Evolution As Your Competitive Edge

Finally, opting for a customized coated fabric can be tremendous for your business relationship. Your customers will appreciate quality products. Retaining customers in the modern environment is one of the hardest challenges for a business. A great way to gain trust is to ask for feedback on your product’s performance but more importantly to act on that and be able to deliver accordingly.

When should you contact a manufacturer of technical coated textiles?

For the properties and characteristics of the fabric to be carefully determined for optimal performance of the project’s application and to best fit your production capabilities, the ideal stage to contact a technical textile manufacturer as early as possible in the process preferably to consult in the R&D phase.

How Erez is the right coated fabric manufacturing partner to streamline your selection process

When it comes to coated technical textile manufacturing, Erez proudly stands as an industry leader with a 40-year history of innovation and problem-solving. Having worked together with several industries, the business has extensive knowledge of the types of failures coated textile materials go through and how to stop them.

With Erez, you’ll never be worried about raw material quality when working on coated textile products. From physical parameters like the thickness, weight, and adhesion to performance parameters, Erez will consider everything and deliver the perfect solution in the shortest time.

Apart from its advanced R&D and production, Erez has also perfected its supply chain systems. Erez has multiple partners across the globe and guarantees timely deliveries to all its customers. It continues to deliver excellent tailor-made technical coated textile solutions in the best time frame possible even in today’s uncertain market conditions.

Final thoughts

To summarize, opting for customized coated fabric solutions is a better choice because of quality, consistency, and reliability. While generic coated fabrics are both cheaper and readily available, their quality issues and performance characteristics make them unsuitable for products.

Erez’s incredible team of experts and state-of-the-art coated textile manufacturing facility makes it a perfect material supplier for any business. With Erez’s quality and reliable performance, your product will enjoy an undisputed advantage in the market and help your business stay on top.

Share this Post