5 Most Common Fabric Defects that Affect Technical Textile Applications

International Standards, coated textile sourcingMay 15, 2022

You might choose the perfect material, but fabric defects can significantly impact your products. Learning how to identify and avoid them is the best way to ensure consistent performance.

When it comes to technical textile applications, the materials you use play a huge role in ensuring that everything works exactly as it should. That’s why many experts recommend staying extra careful during the material selection process. However, there are some cases where you might select the perfect material but still end up with a problematic product. Fabric defects are among the most common reasons behind that.

Most Common Textile Defects

What makes textile defects dangerous is the fact that they often go unnoticed until it’s too late. Discarding a product obviously wastes both time and resources. However, there is no other choice. Technical textiles are used in many sensitive applications that demand perfection. Moreover, any manufacturing flaws in the product will naturally damage your reputation and hurt the business.

The best way to get ahead of this issue is to learn how to identify common fabric defects. By doing so, you can ensure that the fabric is 100% ready for the application. In case of any textile defect, you can either replace or repair the fabric to eliminate the chances of any problems in the future.

Here are the 5 most common fabric defects you’ll have to deal with in the technical textile world.

Filamentation

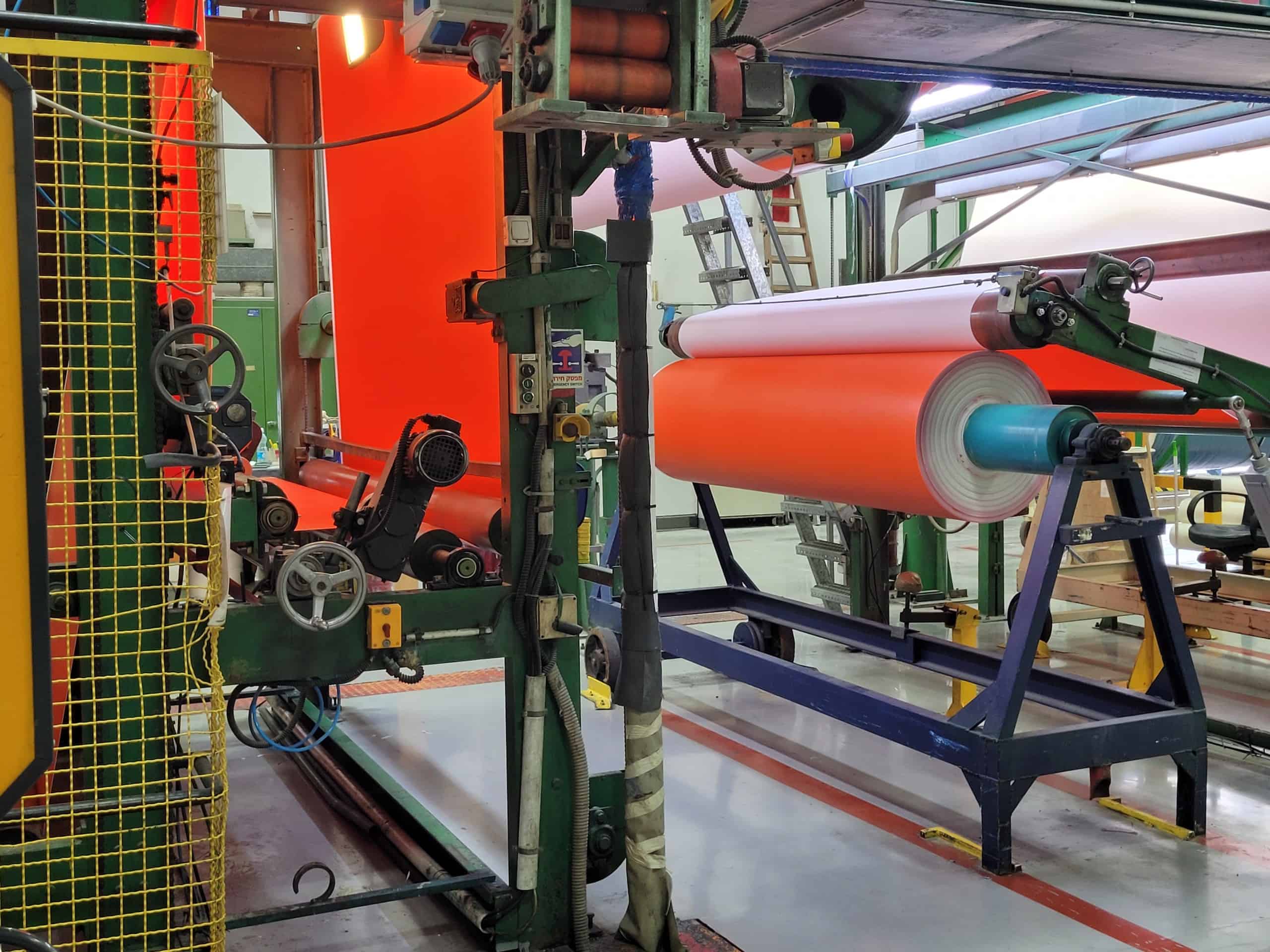

Filament yarns are the building blocks of woven fabrics. Defective threads may lead to breakage between them and affect the overall mechanical properties. You can recognize filamentation in technical fabrics during the process of knife-spreading where a paste forms around the defective area. The paste comes from the topcoat you apply to the fabric, which then protrudes from the surface due to the broken filaments.

Knots

This is another common fabric defect that happens due to negligence while repairing a weaving defect in the fabric. The problem itself is minor but can potentially limit the fabric’s applications and affect its overall chemical resistance. Knots generally protrude to the surface of the fabric and remain uncovered by the coating. Since the coating is primarily responsible for the overall resistance to chemical and environmental factors, these knots can affect the performance and cause issues in the product down the line.

Yarn Contamination

This problem occurs when the yarn is contaminated during the manufacturing process. Generally, the effects are aesthetic as it causes the yarn color to become darker. If you are dealing with a light-colored fabric, yarn contamination will be visible and affect the acceptability of the product. However, the issue can become unnoticeable when you are dealing with darker colors that are closer to gray and black.

Oil Stains

This fabric defect happens due to an issue in the processing machinery. Oil stains can be continuous or sporadic depending on the condition of the machine. The oil generally comes from the bearings of the processing machines or the loom itself and can affect the adhesion and bonding properties of the fabric.

Weft Distortion

Any fabric consists of vertical and horizontal weaving threads (warp and weft). Weft distortion causes the weft thread to change its course from the straight line in relation to the warp and leaves the fabric susceptible to mechanical inconsistencies, especially in inflatable applications where the fabric undergoes a lot of stress.

Experience the Best in Technical Textiles with Erez

Rather than checking and dealing with fabric defects on your own, it’s better to work with a material supplier that ensures 100% defect-free products all the time. Erez is one of the industry leaders in the technical textile market and enjoys a reputation for excellence because of its stringent quality control standards and global experience.

With a team of committed experts who have worked globally across a plethora of industrial applications, Erez brings more experience, versatility, and a history of customer satisfaction to the table. Furthermore, Erez’s commitment to being more than just a material supplier sets it apart. We aim to be a partner who can facilitate optimizing your procurement and other processes.

Before contacting our experts to overcome the textile related challenge you’re currently facing, we recommend reviewing our latest guide to base fabrics in coated technical textiles to find the answer.

Share this Post