Is it Possible to Recycle TPU-Coated Textiles – And is it the Best Option?

Sustainability, coated textile sourcingJan 21, 2019

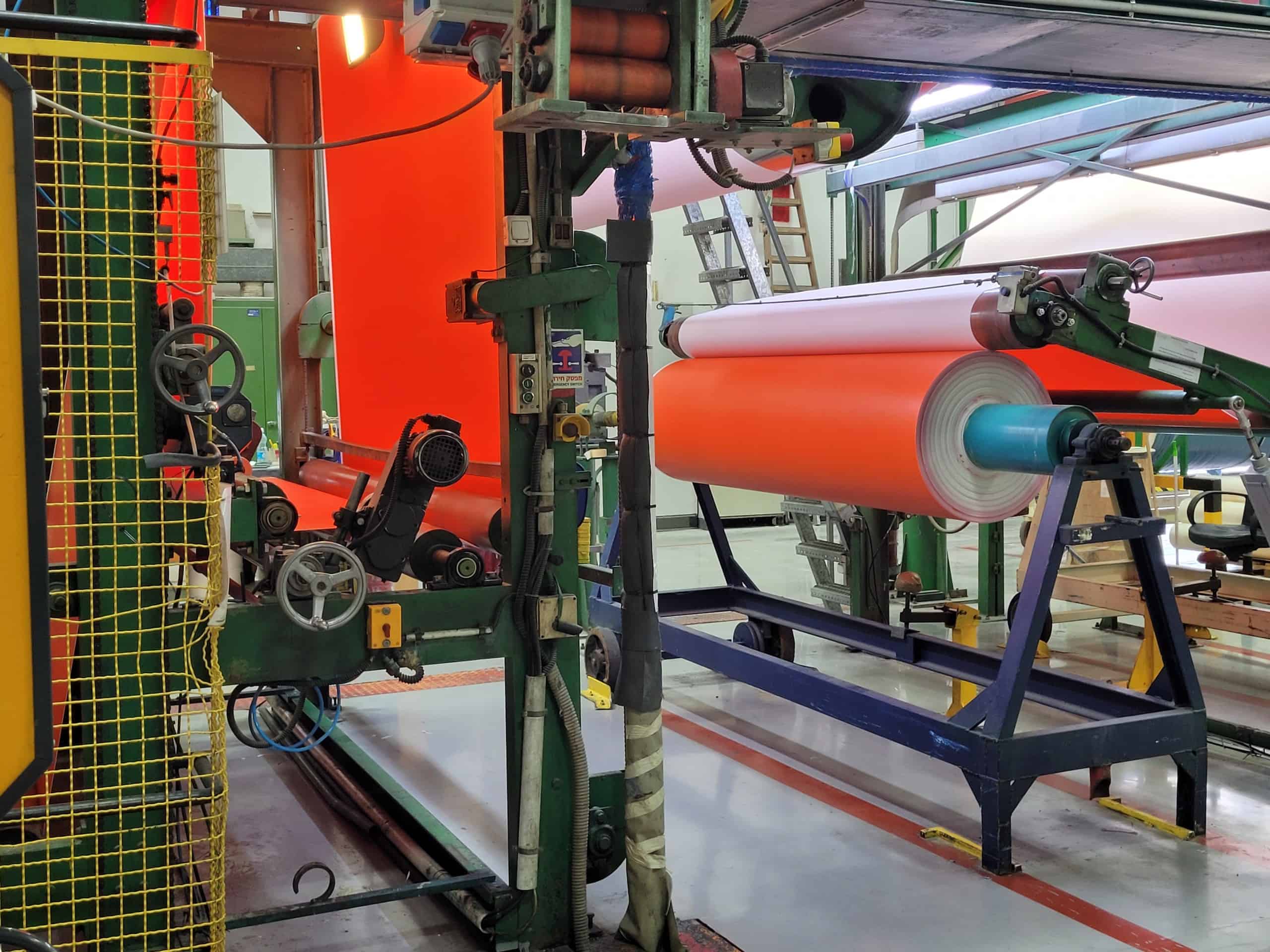

Technically, thermoplastic-coated textiles can be recycled. Chemical processes exist that can retrieve the coating, base material, additives, glues, as well as the chemical solutions used in the dissolution process. And, recycling has many advantages. It can reduce scrap waste by 90-96%. This can save you disposal costs and help conserve valuable raw materials. However, there is still a shortage of facilities that separate the base material from the coating, making recycling expensive at a minimum and impossible most of the time.

Additionally, there is valid concern that the chemical process and energy output required to recycle coated textiles may actually not be the most sustainable EOL. Frequently, the most viable, and possibly the more sustainable, way for the coated-textile manufacturing industry to work toward sustainability is through reuse.

Let’s take a look at the basic chemical recycling processes and its feasibility, and then discuss some other options.

Chemical Recycling

Chemical recycling mechanically grinds the material then introduces chemical solutions that breakdown the polymer materials into their chemical parts. This is a multiple-step process that typically involves first using a physical method to masticate the textile. This can be shredding, grinding, or beating and may include a sieving step.

The resulting mash is put in a bath of solvents to reduce the material to its chemical components. One or more intermediary chemical compounds may be created before arriving at polyols, a raw material used to make polyurethanes. Some methods use heat and a specific gas such as hydrogen to break the chemical bonds.

There are several general types of chemical recycling processes. Which one is used depends on what the initial material is and the desired end result. They are:

Glycolysis: This process combines mixed industrial and post-consumer polyurethanes with co-monomer diols ( such as ethylene glycol) at high heat, causing a chemical reaction that creates new polyols.

Hydrolysis: This process creates a reaction between used polyurethanes and water, resulting in polyols and various intermediate chemicals. The polyols can be used as fuel and the intermediates as raw materials for polyurethane.

Pyrolysis: The application of high heat under an oxygen free environment breaks down polyurethanes to create gas and oils.

Hydrogenation: Similar to pyrolysis, hydrogenation creates gas and oil from used polyurethanes through a combination of heat and pressure and hydrogen.

The polyols are separated from the other compounds. They are cleaned and condensed into powder or pellets, then used to create new coating material. These “new” polyols maintain the properties and functionality of the original polyols and are able to be used in the same ways as the original material.

Unfortunately, chemical recycling of coated textiles is still expensive, suffers from logistical issues, and lack of process flexibility. So, few plants have been built. The plants that do exist are typically small. This makes the recycling impossible for most of the market.

Coated Textile Reuse

Attempts have been made to find other approaches to make the product life cycle more environmentally friendly. Most efforts focus on extending new-product service life and reusing old products that have exceeded their useful lives. Erez is active in both these areas.

By creating the highest quality products possible, Erez aims to minimize the amount of new coated textiles that are introduced into the environment. By working exclusively with coating options that are weldable, tears and damaged products can often be re-welded instead of discarded.

Coated textile reuse can take many forms. For Erez, creating a sustainable EOL for coated textiles has been a top priority for many years. Erez partners with manufacturers globally who specialize in coated textile reuse, and who take coated textiles at the end of their product life cycle and repurpose them into a wide range of second-life products – from woven mattresses to water containment for livestock, the possibilities are endless.

We’ll discuss these in more detail in a future article. If you are interested in moving toward a more sustainable product lifecycle, Erez can help you assess your situation and help provide solutions. Contact an Erez specialist today and let us show you how.

Share this Post