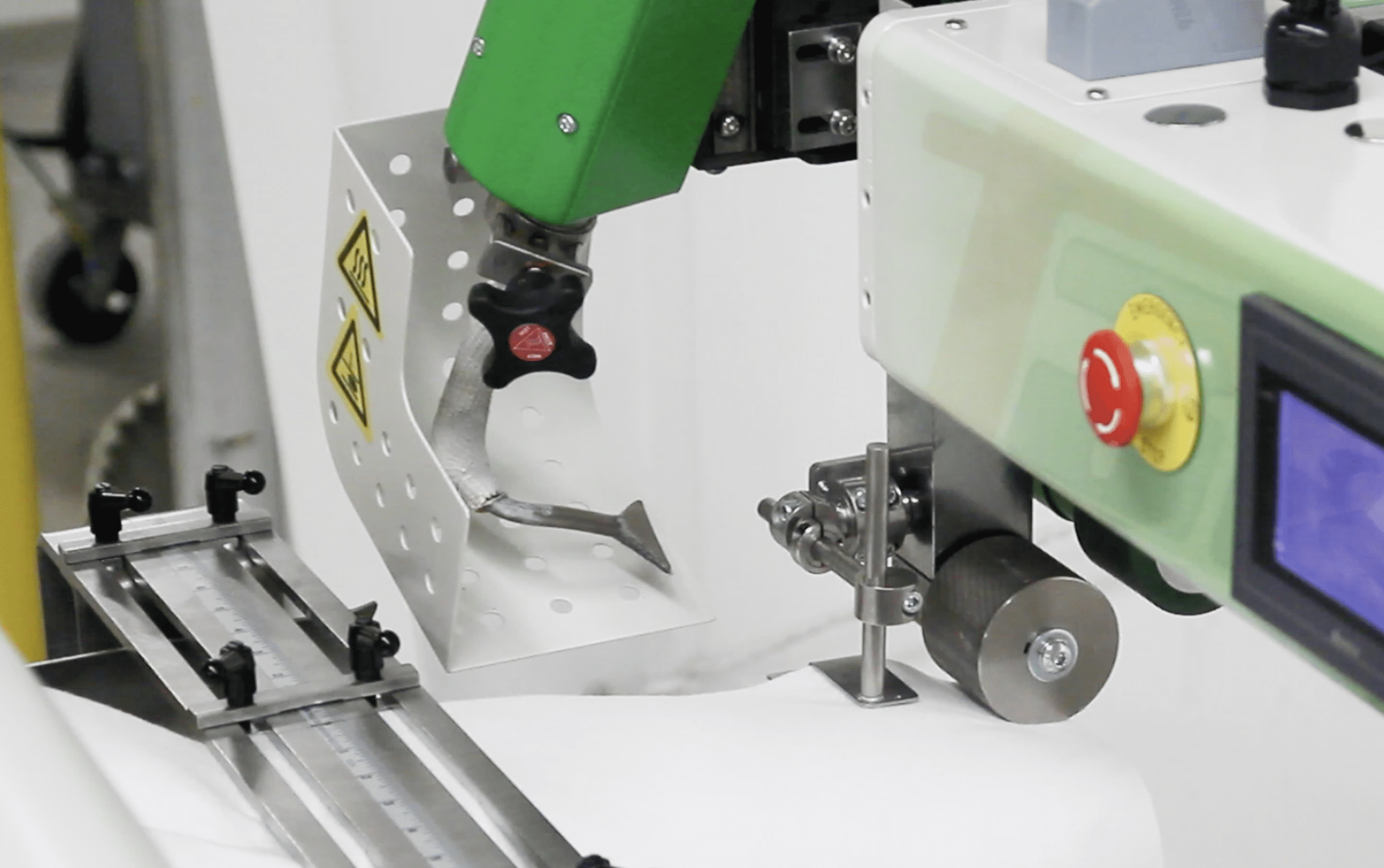

Image courtesy of Miller Weldmaster

Thermoplastic product manufacturers often use welding to seal technical textiles during product manufacturing. This enables the creation of all kinds of coated textiles products involving complex shapes, large surfaces, and waterproof constructions of high durability.

In this article, we present the considerations manufacturers should make when choosing a welding method, depending on their needs and the specifics of each application. We’ll also discuss Hot Air Welding and when it should be implemented.

Identifying Welding Needs

The first step a manufacturer should take is to identify the characteristics required from the welding technique. Are only long straight welds required, or should the method be able to accommodate curves? How much does speed factor into the equation? Lastly, more specialized weld characteristics have to be taken into consideration, such as leak-proof seal reliability, reduction of labor costs, and improving product lifespan.

Welding Application Considerations

Apart from looking into the resulting weld characteristics, there are some application-specific considerations that manufacturers need to take into account. Regarding size, welding machines range in size from nearly portable, to mid-sized tabletop devices, all the way to standalone automated machines. Required safety measures is another factor since welding machines involve either extremely hot implements or even high-frequency wave radiation. Lastly, the required operators training and return on investment (ROI), are factors that need to be taken into account and can heavily influence the welding method selection.

Welding Method Options

With regards to the actual welding methods, there are three methods that are most prominent. First is high-frequency (HF) welding, also known as radiofrequency (RF) or dielectric welding. In this method the layers of thermoplastic material are fused together, using high-frequency electromagnetic energy. The coated textile layers act as a dielectric and are fused together through heat, generated by the HF wave radiation.

The second method is hot wedge or bar welding, which uses a heated metal wedge to provide the required heat. The technical textiles are pressed together with two pinch rollers, pulled from each side of a heated wedge that concentrates the heat on the weld, forming a fused bond between textile layers.

Lastly, the third method is hot air welders, which operate by blowing compressed air heated up to 750°C (1382°F). The resulting hot air is precisely injected at the welding point between the fabrics, forming a tight seal.

Method Highlight: Hot Air Welding

Hot air welders can have excellent portability, available even in the form of handheld devices. Moreover, they also come in fully automated welding machines, where they are currently the fastest welding technology available. In terms of ROI, amortization of purchase cost for most hot air welders occurs in less than 1.5 years.

Applications

Hot air welding is an ideal choice for materials with a thickness of 0.2 – 3mm. This type of welder can accommodate a variety of different welding widths. It’s a suitable welding method when starting and stopping is required and can result in completely safe, airtight seals which make it suitable for inflatable boats and other applications where a perfect weld seal is required.

For a more comprehensive and detailed analysis of coated textiles welding methods, download Erez’s guide to welding methods for technical textiles:

Share this Post